Products

Specification

| Type | chemical | Diameter(mm) | Sheath thickness(mm) | Powder weight(g/m) |

| CaSi Wire | Si50 Ca28 | 13 | 0.4-0.45 | 220 |

| Si55 Ca28 | 13 | 0.4-0.45 | 220 |

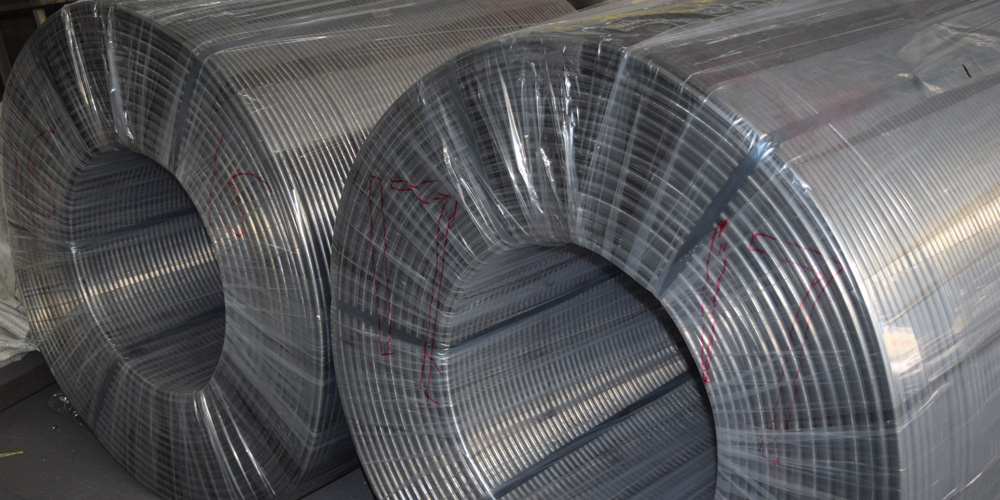

Calcium Silicon Cored Wire

Alloy cored wire is used for steelmaking. It can purify and improve the castability of the molten steel, and significantly improve the yield of the alloy.

Calcium silicon cored wire is one of the most commonly used models. It is a compound alloy made up of elements silicon, calcium, and iron, is an ideal compound deoxidizer, desulfurization agent. At present calcium alloy can be used instead of aluminum for final deoxidation, is applied to high-quality steel, special steel and special alloys production. Such as rail and low carbon steel, stainless steel, steel and nickel base alloy. titanium alloy and other special alloy.

Alloy Cored Wire is conducive to the adjustment and control of the content of easily oxidizable elements and trace elements, it can greatly improve the yield of the alloy, reduce the smelting cost, shorten the smelting time and precisely control the composition.

Cored Wire technical specifications:

(1) Wire diameter: 13±0.8mm.

(2) Thickness of the steel: 0.4mm±0.2mm.

(3) Powder contain: 225g/m ±10g/m.

(4) Ratio powder/steel: 60/40.

(5) Wire length: 5000-5500m.

(6) Coil weight: 1000-1800kgs.

(7) Coil width: 600-800mm

(8) Wire winding: horizontal

(9) Packing: in steel cages covered with plastic

Alloy Cored Wire Specification:

| Type | chemical | Diameter(mm) | Sheath thickness(mm) | Powder weight(g/m) |

CaSi wire | Si 50-60% Ca 20-30% | 13±0.8 | 0.35-0.5 | 220±10 |

| CaFe Wire | Ca 30-40% Fe 60-70% | 13±0.8 | 0.35-0.5 | 250±10 |

Carbon wire | C 80-98% | 13±0.8 | 0.35-0.5 | 135±10 |

| FeTi Wire | Ti 30-40% | 13±0.8 | 0.35-0.5 | 380±10 |

Pure Ca wire | Ca≥97% | 9-10 | 0.4-1.0 | 55-67 |

| ReSiMg Wire | Si 42-50% Mg 5-35% Re 2-6% | 13±0.8 | 0.35-0.5 | 240±10 |

| FeS Wire | S 48% | 13±0.8 | 0.35-0.5 | 300±10 |

Other specifications can be made according to customers requirement