Products

Specification

| Grade | Chemical Composition(%) | |||||

| Si | Al | Ca | P | S | C | |

| FeSi75A | 74-80 | 1.5 | 1.0 | 0.035 | 0.02 | 0.1 |

| FeSi75B | 72-80 | 1.5 | 1.0 | 0.04 | 0.02 | 0.2 |

| FeSi75A | 74-80 | 2.0 | 1.0 | 0.035 | 0.02 | 0.1 |

| FeSi75B | 72-80 | 2.0 | 1.0 | 0.04 | 0.02 | 0.1 |

| FeSi75C | 70-80 | 2.0 | 0.04 | 0.02 | 0.2 | |

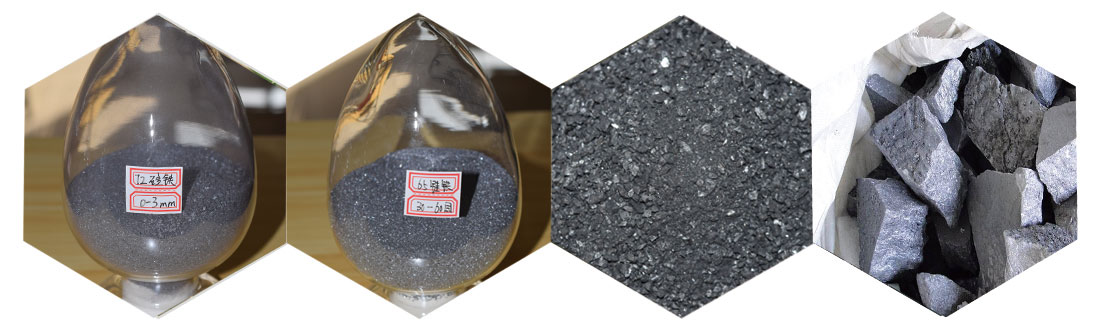

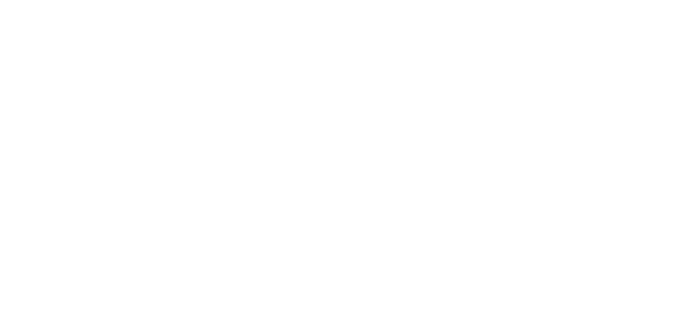

Size 10-80mm 0-3mm or customized.

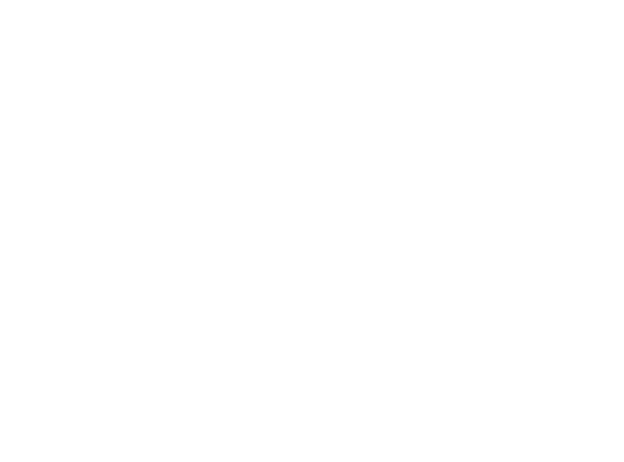

Ferro Silicon Introduction:

Ferro silicon alloy is composed of silicon and ferrum. Silicon and oxygen are easily synthesized SiO2, so FeSi is used as deoxidizer in steelmaking. When SiO2 is formed, it releases a lot of heat at the same time, so the temperature of molten steel increases. Also, FeSi is widely used in the production of low-alloy steel, spring steel, bearing steel, resistant Steel, and electrical silicon steel.

It is mainly used in the manufacture of steel and cast iron and produces fine-quality steel. According to the content of silicon, this product can be divided into FeSi with Si content of 75%, 72%, 65%, 60% and 45%.

USES OF FERRO SILICON:

Ferro Silicon is made available in different composition as per the requirements of the clients. It may be low Al, High Purity or low C Ferro Silicon.

It is used in the production of special steel qualities and better durability.

Our special grades of Ferro Silicon help to keep both the content of inclusions and the carbon content in the final steel at low levels.

Ferro Silicon is used as raw material high-purity quartz, charcoal and iron ore in the production of arc furnaces.